Fanuc Cnc Lathe Programs

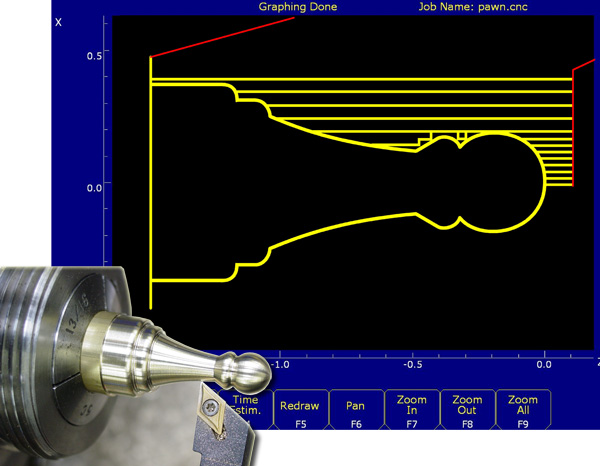

Posted : adminOn 11/9/2017NC to Fanuc CNC Systems GE Fanuc Control History photos and control Specifications, GE Fanuc CNC Controls for legacy products with data sheets. Predator Virtual CNC software for 3. D CNC machine simulation, CNC verification, setup sheets and reverse engineering. What is Predator Virtual CNC Predator Virtual CNC is software designed to simulate and verify operation of your CNC machines on your PC. By simulating the machining process off line you literally save thousands of dollars in lost time, scrapped parts, broken tools and machine crashes while improving overall machine productivity. Why use Predator Virtual CNC Running a profitable manufacturing shop floor is challenging. And keeping it productive is tough work. Those that succeed embrace technology. Thousands of manufacturers and job shops rely on Predator Virtual CNC to keep their CNC machines running reliably while minimizing errors. Prove out processes offline. Simplify CNC Setup. Minimize Waste. Organize release to shop floor process. Reduces tooling costs. Saves coolant and raw materials. Reduces wear and tear. Lathe Head stock or spindle Alignment. Check spindle alignment by chucking up a piece of material and performing a cut. The material should be a minimum diameter of 2. Predator Software creates DNC, MDC, PDM, SFC, Virtual CNC, Travelers and Tracker software for shop floor control and automation of manufacturers. Verify surface finish. Verify feature dimensions. Confirm tool motion and clearances. English/index.4.JPG' alt='Fanuc Cnc Lathe Programs' title='Fanuc Cnc Lathe Programs' /> Get started quickly and easily. Choose from four editions Predator Virtual CNC 2 Axis. Predator Virtual CNC 3 Axis. Predator Virtual CNC 4 Axis. Predator Virtual CNC 5 Axis. Includes the following features. Fanuc Series 18i Pdf User Manuals. View online or download Fanuc Series 18i Connection Manual. Fanuc G71 Turning Cycle G71 turning cycle is used for roughmaterial removal from a cnc lathe component. G71 turning cycle makes large diameter cutting eas. Fanuc-Lathe-Programming-Example-Using-G71-G70-for-ID-Machining.jpg' alt='Fanuc Cnc Lathe Programs' title='Fanuc Cnc Lathe Programs' />

Get started quickly and easily. Choose from four editions Predator Virtual CNC 2 Axis. Predator Virtual CNC 3 Axis. Predator Virtual CNC 4 Axis. Predator Virtual CNC 5 Axis. Includes the following features. Fanuc Series 18i Pdf User Manuals. View online or download Fanuc Series 18i Connection Manual. Fanuc G71 Turning Cycle G71 turning cycle is used for roughmaterial removal from a cnc lathe component. G71 turning cycle makes large diameter cutting eas. Fanuc-Lathe-Programming-Example-Using-G71-G70-for-ID-Machining.jpg' alt='Fanuc Cnc Lathe Programs' title='Fanuc Cnc Lathe Programs' /> Axis, 3 Axis, 4 Axis and 5 Axis CNC Machines. Rotate Movie File Online. Mills, Lathes, MillTurns, Lasers, Waterjets and Routers. Solids based Verification and Simulation. Micro Machining support Supports MillionthsG and M code APTCL, NCI and INC support Error and Collision Detection Part Inspection prior to machining Includes support for over 1. CNCs User configurable Reverse Post Processor. Automatic Gouge Detection. Multiple parts, fixtures, tombstones and processes. Advanced tooling. Complex stock and fixtures. CAD Compare for Designed vs. MachinedMachine simulation. Integrated Editor. Predator API and Active. X development platform. Online help topics. Axis CNC Mills, Lathes, Lasers, Waterjets Routers. Predator Virtual CNC supports all standard vertical, horizontal and complex machine configurations with. User definable machine tool configurations with our flexible reverse post processors allows standard VMCs and HMCs to be supported. Standard milling. Advanced cycles. include subs, macros, variables, trig and logic codes are all. Axis Mold and Die Machining. Predator Virtual CNCs Turbo Milling technology is optimized for 3 axis surface machining. Processing. speeds can be up to 2. Complex 4 and 5 Axis Machining. Full support for simultaneous 4 and 5 axis machining on mills and millturn machines. Optionally define your entire machine for full collision detection of any moving part. Support for rotary heads, rotary tables, nutated heads, nutated tables and multiple spindles are all supported. Axis Lathes and MillTurn Machines. Predator Virtual CNC supports 2, 3, 4 5 axis turning and complex MillTurn machines with live C and Y axis motion. User definable machine tool configurations combined with our comprehensive library of reverse post processors allows standard HTLs and VTLs to be supported. Standard lathe facing, turning, threading, grooving, roughing and drilling cycles are all supported. NOTE Predator Virtual CNC does not support pinch turning, sub spindle transfers, parts catchers and swiss style turning. G M Codes and APTCL Support via Configurable Reverse Post. Predator Virtual CNC includes 1. A 2. 30 page reverse post manual documents all of the options available to support a wide range of CNC machines. Specific reverse posts to each of your machines can also be purchased. Master. CAM and Surf. CAM Support. Predator Virtual CNC supports Master. CAM NCI files and Surf. CAM INC files. Error and Collision Detection. Gouge detection. CNC program syntax errors. Coolant checking. Spindle checking Rapid collisions. Tool collisions Tool shank collisions Tool holder collisions Fixture collisions. Rotary table collisions. Rotary head collisions. Spindle collisions. Machine collisions. Part Inspection prior to actual machining. Predator Virtual CNC provides animated simulation of the machining process. Seeing how the tool behaves under program control provides great reassurance that there are no gross errors in the program and makes the cause of smaller errors easier to diagnose. Rapid zoom, rotate, pan and cross sectioning of solid model views allows errors to be seen, even if they are hidden from the original view or are inside the part. Predator Virtual CNC includes feature based inspection and inspection capability. Feature based inspection measures part features, dimensions and the relationship between separate features. Predator Virtual CNC recognizes edges, arcs, cylinders, planes, surfaces and cones. To select a feature, all you need to do is click on the feature using the mouse. CAD Compare for Designed vs. MachinedPredator Virtual CNC includes an option to compare the machined part back to the designed part within any tolerance. Users can define a tolerance above and below which excess material. The tolerance can be adjusted at any time without reprocessing the job. Using Predators CAD Compare capability in conjunction with. Part inspection allows deviations from the design model to be measured at any point on the part surface. Complex Tooling, Stock and Fixtures. Predator Virtual CNC includes support for 1. Custom tool shapes, custom tool shanks, and custom holders are all supported. An unlimited number of tool libraries provides tool kits per machine, per customer, etc. Predator Virtual CNC supports 1. Complex stock and fixtures can be importing via STL files. Full collision detection is supported for chucks, jaws, face plates, tail stocks, tombstones, pallets, clamps, vices, etc. Integrated Editor. Edit CNC programs within Predator Virtual CNC and reprocess the simulation at any time. Set global or line specific breakpoints to debug complex CNC programming challenges. Predator API and Active. X SDKPredator Virtual CNC includes an open development and comprehensive API application programming interface with 3. Even easier is an Active. X control that you can drop into your existing project. Several source code examples are available and you have the flexibility of using C, VB, VB script, Delphi and other compatible programming languages. Predator Virtual CNC Part Numbers. Part Description. Predator Virtual CNC 2 Axis Lathe Only. Predator Virtual CNC 3 Axis MillLathe. Predator Virtual CNC 4 Axis MillLathe. Predator Virtual CNC 5 Axis MillLathe. Predator Virtual CNC Options Part Numbers. Part Description. Predator CAD Compare STL2. Predator Virtual Machine 2 Axis Lathe. Predator Virtual Machine 3 Axis Mill Lathe. Predator Virtual Machine 4 Axis Mill Lathe. Predator Virtual Machine 5 Axis Mill Lathe. Predator Floating License Manager Learn more Predator Virtual CNC Express Part Numbers. Part Description. Predator Virtual CNC Express.

Axis, 3 Axis, 4 Axis and 5 Axis CNC Machines. Rotate Movie File Online. Mills, Lathes, MillTurns, Lasers, Waterjets and Routers. Solids based Verification and Simulation. Micro Machining support Supports MillionthsG and M code APTCL, NCI and INC support Error and Collision Detection Part Inspection prior to machining Includes support for over 1. CNCs User configurable Reverse Post Processor. Automatic Gouge Detection. Multiple parts, fixtures, tombstones and processes. Advanced tooling. Complex stock and fixtures. CAD Compare for Designed vs. MachinedMachine simulation. Integrated Editor. Predator API and Active. X development platform. Online help topics. Axis CNC Mills, Lathes, Lasers, Waterjets Routers. Predator Virtual CNC supports all standard vertical, horizontal and complex machine configurations with. User definable machine tool configurations with our flexible reverse post processors allows standard VMCs and HMCs to be supported. Standard milling. Advanced cycles. include subs, macros, variables, trig and logic codes are all. Axis Mold and Die Machining. Predator Virtual CNCs Turbo Milling technology is optimized for 3 axis surface machining. Processing. speeds can be up to 2. Complex 4 and 5 Axis Machining. Full support for simultaneous 4 and 5 axis machining on mills and millturn machines. Optionally define your entire machine for full collision detection of any moving part. Support for rotary heads, rotary tables, nutated heads, nutated tables and multiple spindles are all supported. Axis Lathes and MillTurn Machines. Predator Virtual CNC supports 2, 3, 4 5 axis turning and complex MillTurn machines with live C and Y axis motion. User definable machine tool configurations combined with our comprehensive library of reverse post processors allows standard HTLs and VTLs to be supported. Standard lathe facing, turning, threading, grooving, roughing and drilling cycles are all supported. NOTE Predator Virtual CNC does not support pinch turning, sub spindle transfers, parts catchers and swiss style turning. G M Codes and APTCL Support via Configurable Reverse Post. Predator Virtual CNC includes 1. A 2. 30 page reverse post manual documents all of the options available to support a wide range of CNC machines. Specific reverse posts to each of your machines can also be purchased. Master. CAM and Surf. CAM Support. Predator Virtual CNC supports Master. CAM NCI files and Surf. CAM INC files. Error and Collision Detection. Gouge detection. CNC program syntax errors. Coolant checking. Spindle checking Rapid collisions. Tool collisions Tool shank collisions Tool holder collisions Fixture collisions. Rotary table collisions. Rotary head collisions. Spindle collisions. Machine collisions. Part Inspection prior to actual machining. Predator Virtual CNC provides animated simulation of the machining process. Seeing how the tool behaves under program control provides great reassurance that there are no gross errors in the program and makes the cause of smaller errors easier to diagnose. Rapid zoom, rotate, pan and cross sectioning of solid model views allows errors to be seen, even if they are hidden from the original view or are inside the part. Predator Virtual CNC includes feature based inspection and inspection capability. Feature based inspection measures part features, dimensions and the relationship between separate features. Predator Virtual CNC recognizes edges, arcs, cylinders, planes, surfaces and cones. To select a feature, all you need to do is click on the feature using the mouse. CAD Compare for Designed vs. MachinedPredator Virtual CNC includes an option to compare the machined part back to the designed part within any tolerance. Users can define a tolerance above and below which excess material. The tolerance can be adjusted at any time without reprocessing the job. Using Predators CAD Compare capability in conjunction with. Part inspection allows deviations from the design model to be measured at any point on the part surface. Complex Tooling, Stock and Fixtures. Predator Virtual CNC includes support for 1. Custom tool shapes, custom tool shanks, and custom holders are all supported. An unlimited number of tool libraries provides tool kits per machine, per customer, etc. Predator Virtual CNC supports 1. Complex stock and fixtures can be importing via STL files. Full collision detection is supported for chucks, jaws, face plates, tail stocks, tombstones, pallets, clamps, vices, etc. Integrated Editor. Edit CNC programs within Predator Virtual CNC and reprocess the simulation at any time. Set global or line specific breakpoints to debug complex CNC programming challenges. Predator API and Active. X SDKPredator Virtual CNC includes an open development and comprehensive API application programming interface with 3. Even easier is an Active. X control that you can drop into your existing project. Several source code examples are available and you have the flexibility of using C, VB, VB script, Delphi and other compatible programming languages. Predator Virtual CNC Part Numbers. Part Description. Predator Virtual CNC 2 Axis Lathe Only. Predator Virtual CNC 3 Axis MillLathe. Predator Virtual CNC 4 Axis MillLathe. Predator Virtual CNC 5 Axis MillLathe. Predator Virtual CNC Options Part Numbers. Part Description. Predator CAD Compare STL2. Predator Virtual Machine 2 Axis Lathe. Predator Virtual Machine 3 Axis Mill Lathe. Predator Virtual Machine 4 Axis Mill Lathe. Predator Virtual Machine 5 Axis Mill Lathe. Predator Floating License Manager Learn more Predator Virtual CNC Express Part Numbers. Part Description. Predator Virtual CNC Express.